I drafted, created, and installed the soft goods components of this high-tech batting cage. I was contracted by Volvox Labs, an experiential design/fabrication studio based in Brooklyn. They had been hired by the SAS analytics firm. I was the only soft goods specialist, and was completely in charge of that aspect of the project from technical design through final installation.

My predominant concern was safety. As there was no existing structure which resembled our project, I did not have a comprehensive set of regulations with which to guide my process. Therefore, I conducted research on sport equipment safety standards and sourced stress-tested and certified materials. Finding material which could act as both a projection screen and adequate shock absorption was difficult. Ultimately, I went with material intended for use as boat sails, and constructed it using marine rigging techniques.

Prior to its final installation in North Carolina, we fully assembled the structure in Volvox Labs' Brooklyn studio. There, we completed our own stress test, calling in several minor-league professional baseball players to use the cage. It successfully withstood repeated impacts at over 100 mph.

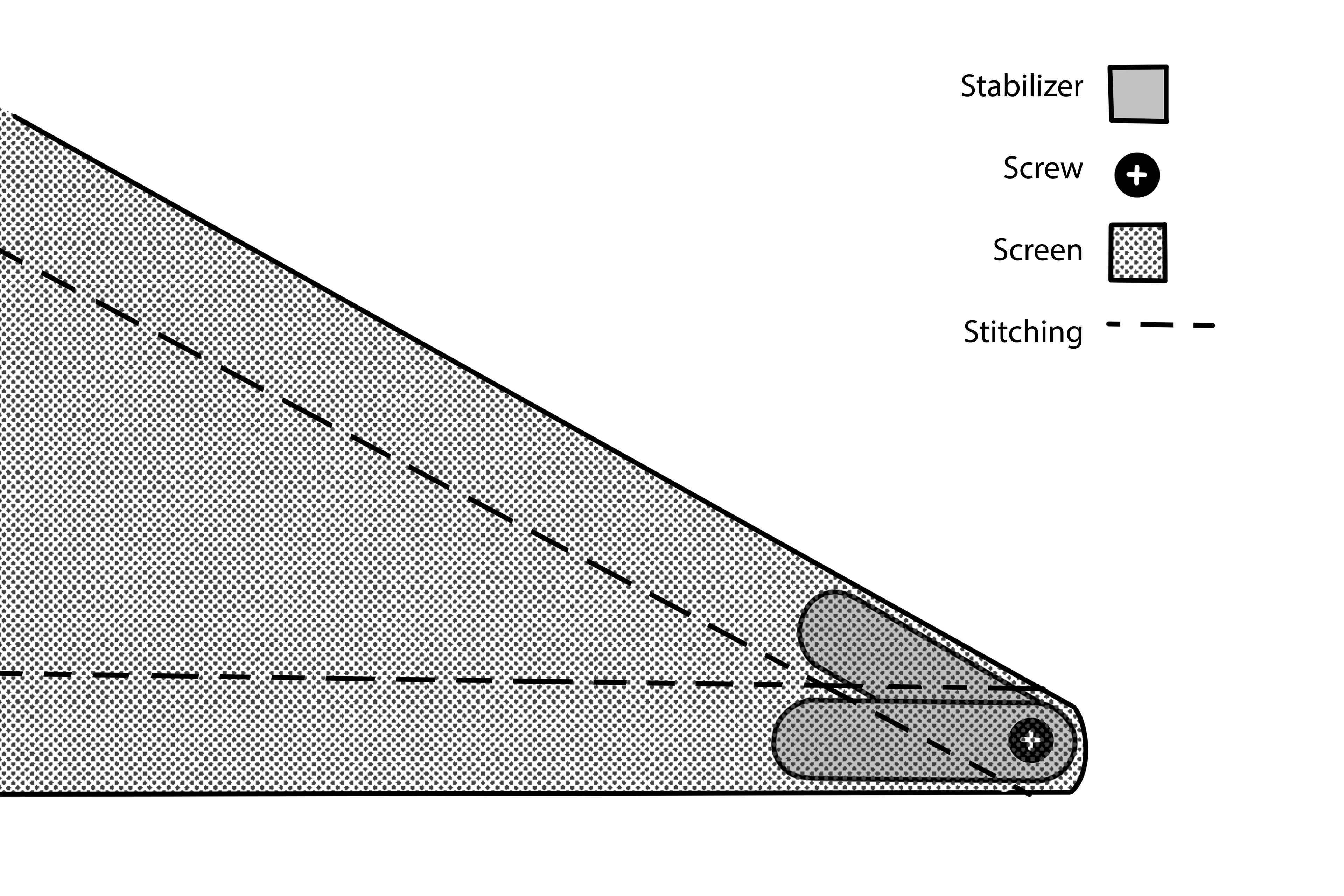

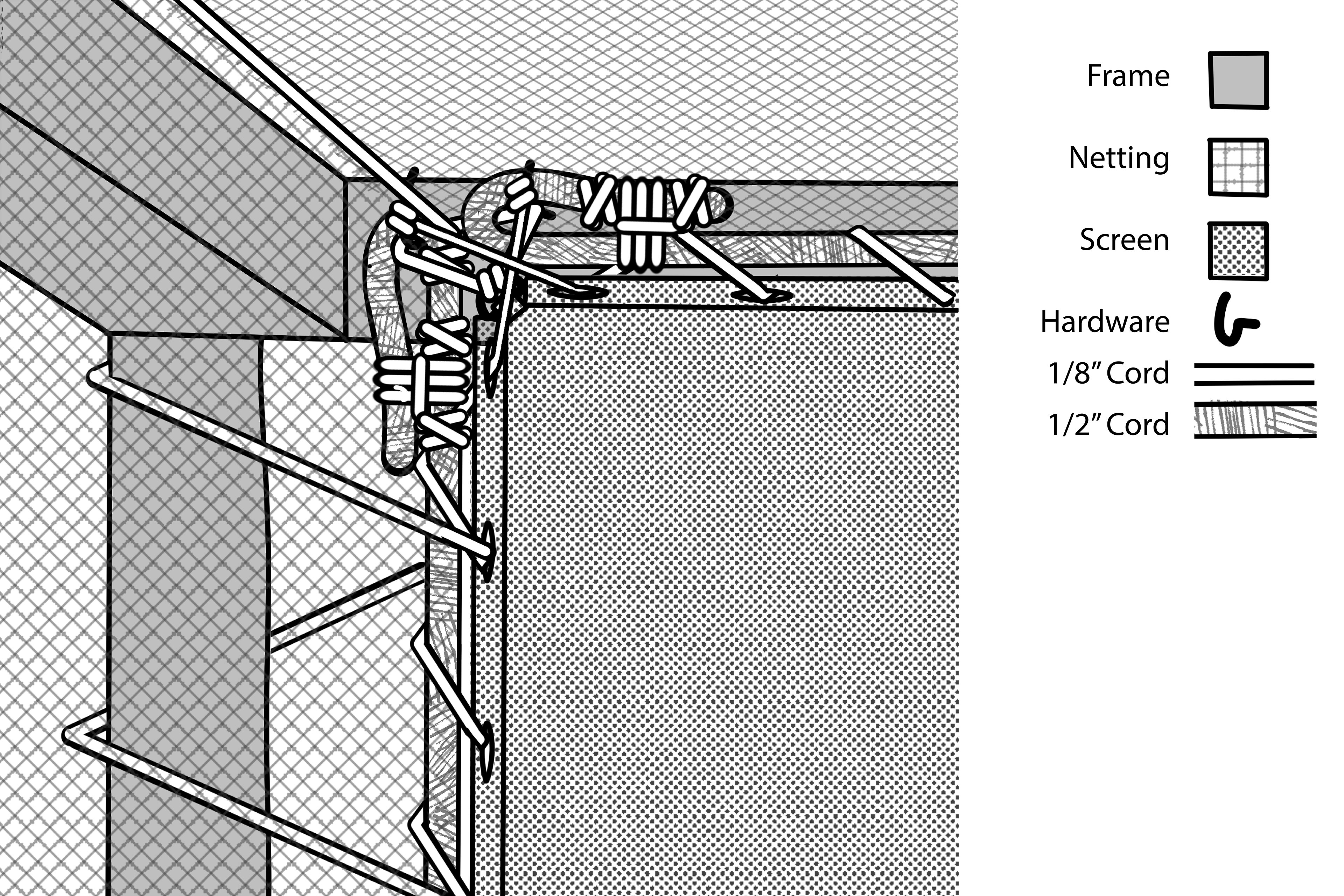

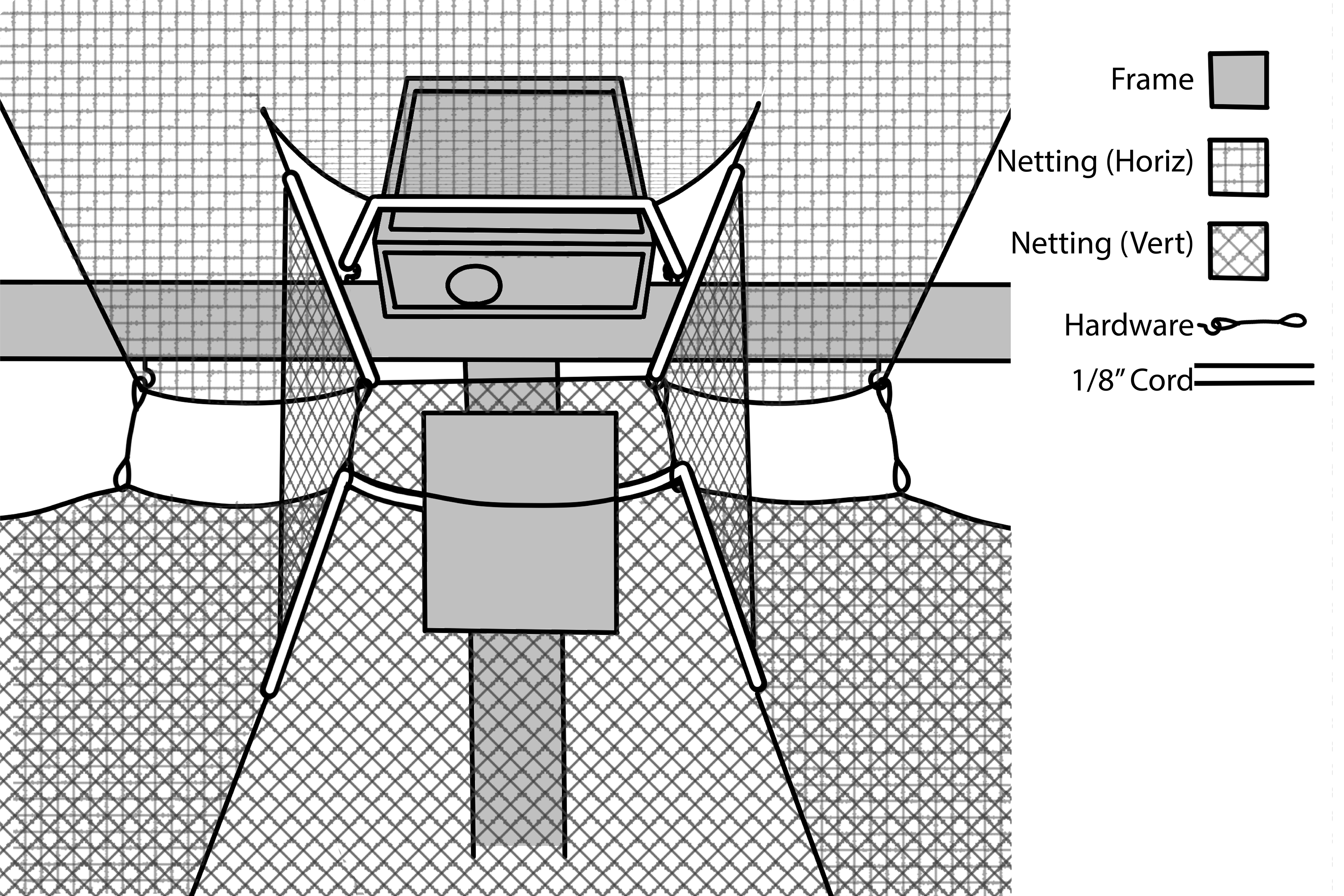

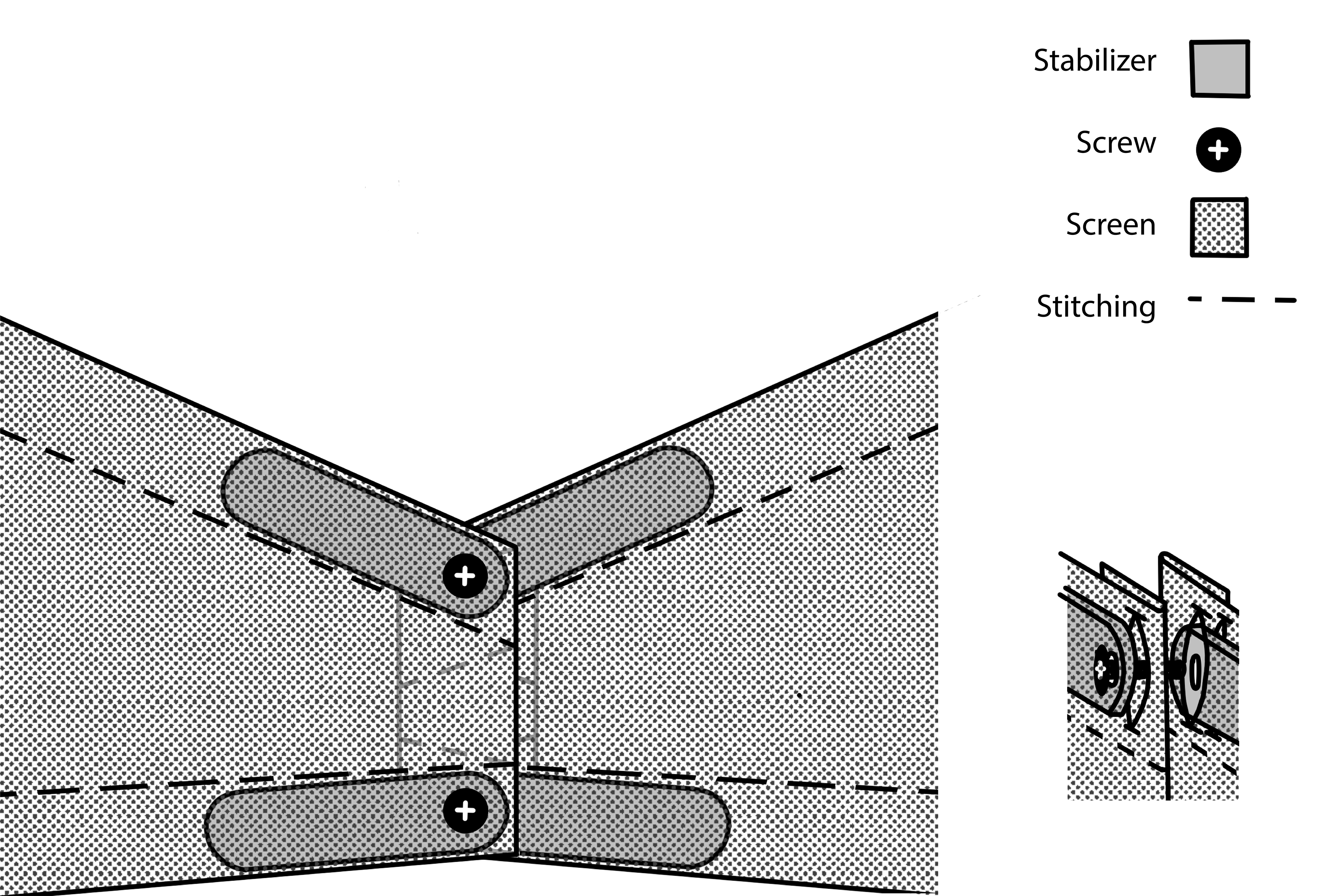

There were three projection screens: the two side pieces, which were over 40 feet long, and a 10'x10' panel at the front. these were attached first. Afterward, I attached the netting panels, which served not only as safety components, but a source of tension which countered gravity's effects on the heavy projection panels.

The edges of the netting were not strong enough on their own to hold the entire weight of the stretched net. To prevent the strings along the edges form snapping, I hand-wove a length of tie-line, which functions as a thin rope that can bear heavy loads, through all of the netting connection points.

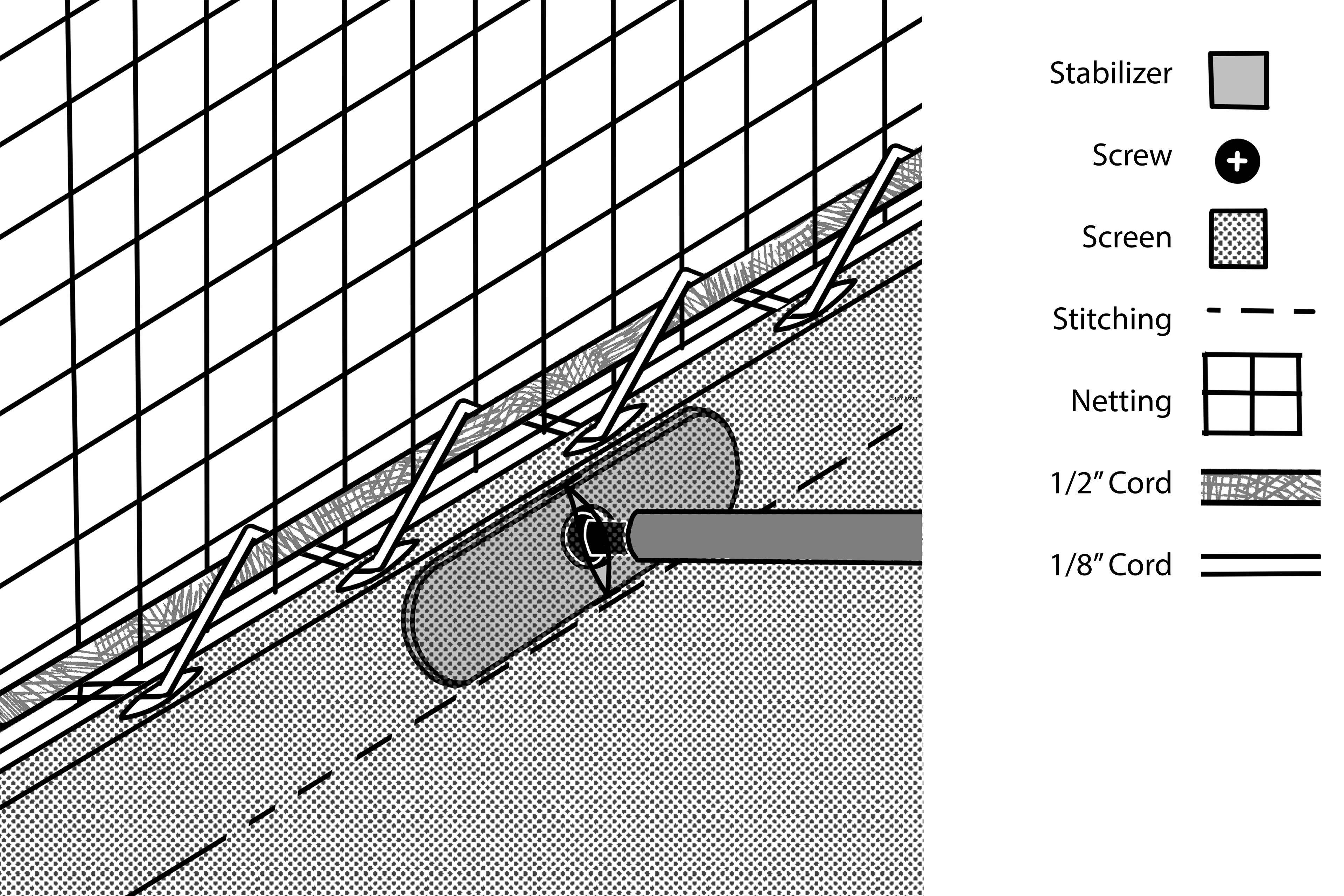

It was necessary to plan for the structure to be dis-and re-assembled several times after Volvox Labs' work was done. Therefore, I created a detailed manual explaining how to safely take down and reinstall the soft good components of the structure, including diagrams and step-by-step instructions.

Below is a link to a Today.com video segment showing the batting cage in use.